November 22, 2023

Troubleshooting & Supplies 3d Printing Additive Manufacturing Sbu Libraries At Southwest Baptist College Libraries

3d Printer Repairing Guide Being mechanical gadgets with numerous controlled aspects, a 3D printer need to be tuned correctly in order to enjoy successful 3D prints. Also devices that are thought about "not broken" and "in excellent working order" can very easily create bad 3D prints otherwise established correctly. The desired version has been cut properly as well as the printer has actually been configured, nevertheless, absolutely nothing shows up out of the nozzle bar the tinyiest little bit of oozing plastic. If you are lucky this can be identified beforehand as the top quality of your prints will certainly reduce as the quantity of carbonised filament rises. The print divides from the print bed and also move during printing. After some printing time, a round of material can develop around the nozzle.- Once you got the clog displaced, try cleansing filament (seeFLOSS, a high-performance cleansing filament).

- If made use of with treatment and stabilized versus the extrusion multiplier, this can conquer some circumstances that your favorite slicer can not handle.

- Examine your instruction manual to find out exactly how to disable layer air conditioning as well as stop this trouble.

- Numerous customers experience problems with 3D printing when a version has little call with a platform.

- Examine your 3D printer retraction settings and reduced total amount of retractions taking place and/or minimize retraction distance.

Summary Of Services: Elephant's Foot

Requirement setups in REALvision Pro-- 100 % infill Will the blue benchy float? Criterion settings in REALvision Pro, modified infill with variants. For more factors, the layer splitting up can also be caused by particles, inaccurately blended resin or ghosting of the resin tank.The Women Trailblazing the Tiktok 3D Printing Scene, Part Two - 3DPrint.com

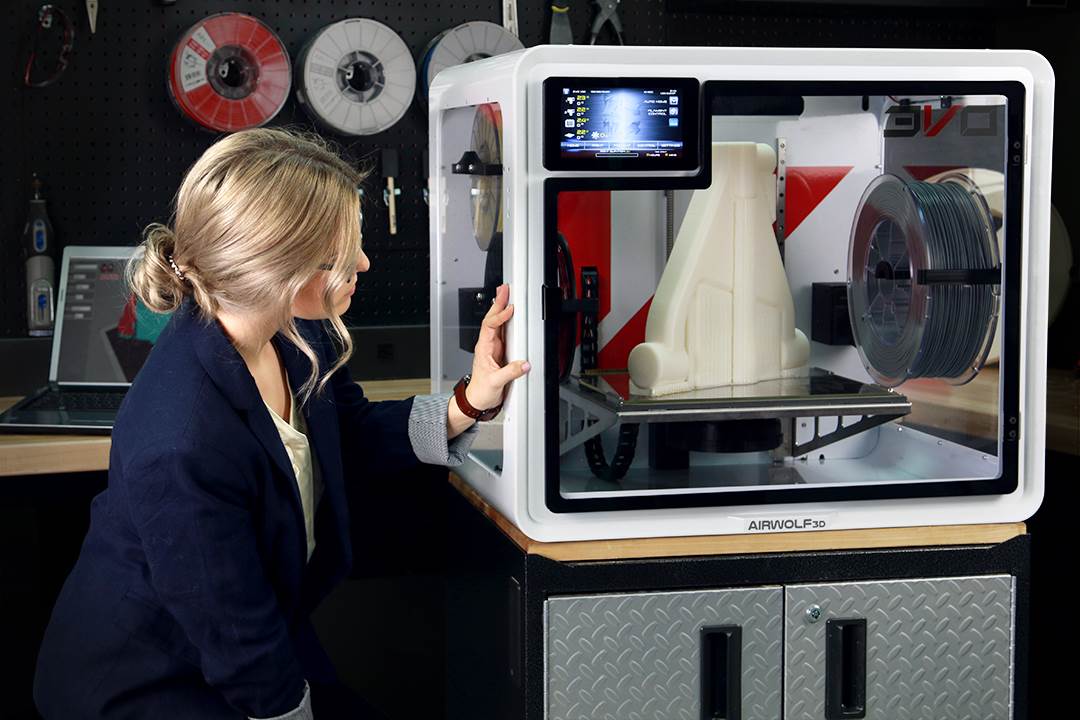

The Women Trailblazing the Tiktok 3D Printing Scene, Part Two.

Posted: Mon, 05 Dec 2022 08:00:00 GMT [source]

Unblock A Clogged Nozzle

If the nozzle is still obstructed, after that the filament might be pushed with one more piece. Warm up the warm end to 220 ° C if you're reusing PLA as well as use another bit of new filament to push this through. But don't do it also hard, so you can stay clear of bending the printer poles. The signs are very easy to https://s3.us-east-1.wasabisys.com/custom-printing/Customization-Trends/offset-printing/leading-ten-ideas-when-starting-with-3d.html ignore-- places of filament or nicks in the wall surfaces as well as print high quality adjustments. The impacts are usually neglected as well as attributed to a variative nature of 3D printing, however in some cases the factors are serious. Cleaning techniques such as Atomic Pull or Cold Pull can assist clear it.What should I check prior to 3D printing?

You'll likewise observe that when PLA spoils, it gets brittle and quickly breaks off.

Print Defects:

The cool temperature level makes the plastic shrink, so it buckles contrasted to what was already published. If you have time for this degree of oversight, it's excellent due to the fact that you can turn off the follower as soon as every little thing is amazing to permit the next layer to adhere. If you can not watch your printer job, you might wish to reduce the filament's temperature level so it will not proceed thawing once it's in location.Social Links