November 7, 2023

3d Printing Troubleshooting: All Troubles & Solutions

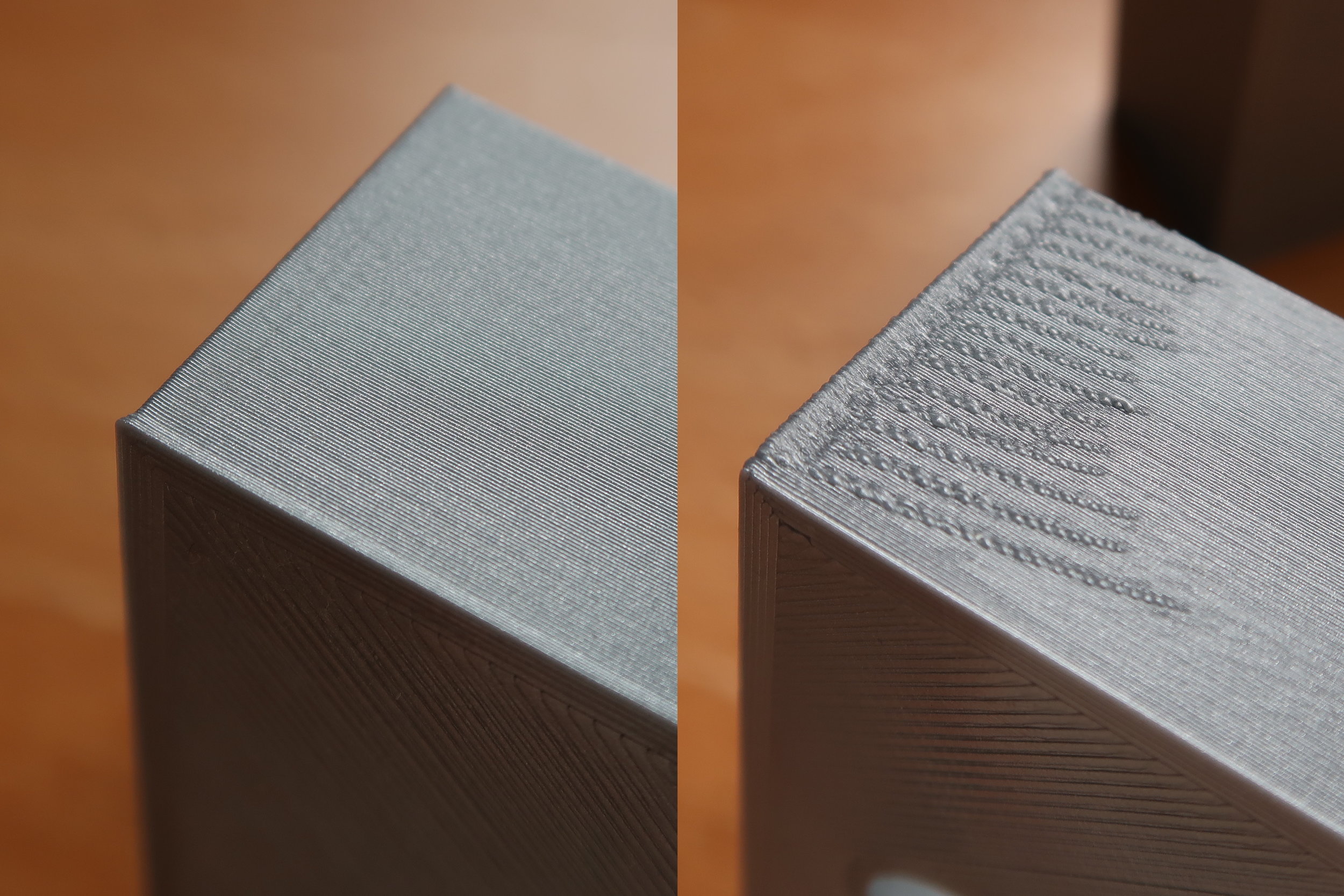

7 Most Usual Troubles With A 3d Printer Just How To Repair The complimentary motion of the nozzle can be changed as well as managed with the slicer setups. Establish that the nozzle takes the quickest possible course to the next printing factor. As a user, you ought to understand the ideal printing temperature levels for the filaments you use. This is yet one more typical 3D printer concern that many novices face. Stringing is a problem that takes place when thin strings of product, similar to hairs, stay externally of a 3D published component, influencing the print's surface area finish.Exactly how do you understand if PLA filament is bad?

Change The Construct Plate Springtimes

Although the printer has a failsafe that makes the electric motor quit to stop further damages, other parts may proceed working. With the open-loop control system, there's no other way for your 3D printer to monitor the head's place. You can input information, and also it will take the nozzle to that location, but there's no warranty that it's publishing in addition to what it should. The head can likewise move during the procedure, not understand the adjustment, and also keep functioning. You can change the elevation by mosting likely to your setups and looking at the layer tab. Pick a size that is 20% smaller than the size of your nozzle to make sure whatever bonds together.- If the value of the 'infill overlap' setting is an absolutely no and even isn't set at all, then the trouble will likely show up.

- Wipe the rods as well as change the oil, and also the trouble may be solved.

- Probably, the 3D printing surface of that layer is over-extruded which's why the nozzle scratched it in the step.

- In this case, nothing is printing due to the fact that the nozzle is also near the print bed.

- Issues with stringing as well as oozing make your 3D prints look unshaven, like a crawler trying to develop an internet in between numerous parts of the framework.

- Even prior to the blockage appears during upkeep you can usually situate certain signs and symptoms such as old filament that is already carbonized showing up inside the nozzle.

First Layer Issues

See the suggestion of the spike in the photo that has actually become molten because of getting too hot. One more equally ruthless as well as somewhat unsafe means is to lantern your nozzle with a blowtorch (after eliminating it from the printer first!). The idea is to warmth as well as melt the clog within the nozzle. This is NOT a technique rigid.ink advise for safety factors.First Professional Wood 3D Printer Released by Desktop Metal - 3DPrint.com

First Professional Wood 3D Printer Released by Desktop Metal.

Posted: Tue, 01 Nov 2022 07:00:00 GMT [source]

Shanty Town 3d Printing Troubleshooting: Absolutely Nothing Is Being Published

Appropriate temperature level is just one of the major conditions that chooses whether the resin will certainly establish or otherwise. If the platform you utilize can be taken into consideration an old one, the response you try to find is that the system becomes over-textured with layers of adhesive. This concern is commonly combined with splits in the glass that get loaded with the filament as well as act as some sort of roots. Actually, there are print systems which contain openings as a component of their layout, so the prints often tend to be tough to separate. In general, the couplers are located in specific areas because they are linked to a stepper motor and https://f004.backblazeb2.com/file/NexaTech/how-to-print-interactive-educational-materials-for-enhanced-learning/index.html also to a specific pole that controls the print head.Driven by Quality: Enabling 3D Printing in Industrial Serial Production – AMS Speaker Spotlight - 3DPrint.com

Driven by Quality: Enabling 3D Printing in Industrial Serial Production – AMS Speaker Spotlight.

Posted: Sat, 04 Feb 2023 08:00:00 GMT [source]

Social Links