November 22, 2023

Additive Production 3d Printing Niosh

Additive Manufacturing 3d Printing Niosh When examining prospective making partners, business take a large range of criterion right into account. Layout capacities cover the checklist but capability to range, prices and experience all follow closely behind. When it involves key use, the disparity in between plastic and steel 3D printing isn't as large as you could assume. More than a third of respondents addressed that they utilize plastics and steels similarly, as well as even between those that chose either plastics or metals, plastics led by just a little over 10%. When we conducted our first study, much of the advantages were still abstract ideas.What is the toughest 3D printing technique?

Polycarbonate. According to several producers as well as reviewers, polycarbonate (COMPUTER) is considered the toughest consumer filament around. Computer can produce incredibly high-strength components when printed correctly with an all-metal hot end as well as an unit.

Discerning Laser Sintering (sls)

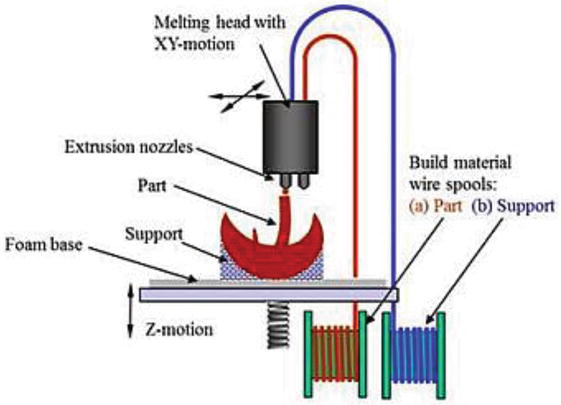

You buy a brand-new print-- this time around, you need it to be functional and cosmetically completed. Your relied on 3D printing partner, Stratasys Direct Manufacturing, publishes up your component in Molten Deposition Modeling, hand sands it down and also ships it back to you done in the period of 5 service days. Today, 3D printing a very early phase layout as well as re-printing it over night is practical as well as affordable thanks to quick prototyping or 3D printing systems like PolyJet and also Stereolithography. Where supports are called for mainly depends upon the material, develop process as well as build resolution, to name a few factors. However you can archive layouts and save them locally till you need to edit them once more. Xometry uses a full range of 3D printing services for your project requires. Visit our Instant Quote Engine to get a totally free, no-obligation quote in minutes. Choose a 3D printer with a straightforward interface, a receptive assistance division, and an enormous area of users.Researchers unveil new AI-driven method for improving additive ... - Argonne National Laboratory

Researchers unveil new AI-driven method for improving additive ....

Posted: Thu, 09 Mar 2023 08:00:00 GMT [source]

Printed Buildings

A great deal of what we print tends to be enclosures and there are some good ideas for those drifting around. Yet if you are just beginning, you ought to look into's video clip of points he wanted a person had informed him when he started 3D printing. Preparing a component for a develop is largely automated with some hands-on communication to excellent component positioning or support creation.- Attempting to device components like these would be either very expensive or perhaps difficult.

- Though it has been around for years, additive manufacturing is still a relatively new innovation compared to traditional manufacturing.

- The selection of solvent is critical for the vapor smoothing procedure, as it needs to be compatible with the material utilized for the 3D published component.

- This innovation offers a regulated spatial distribution of cell or development elements along with the scaffold structures.

- You order a brand-new print-- this time, you need it to be useful and cosmetically ended up.

3D Systems makes Stratasys takeover attempt - TCT Magazine

3D Systems makes Stratasys takeover attempt.

Posted: Fri, 02 Jun 2023 08:56:41 GMT [source]

Social Links