November 22, 2023

What Is 3d Printing And What Is Additive Production? Hp ® Official Site

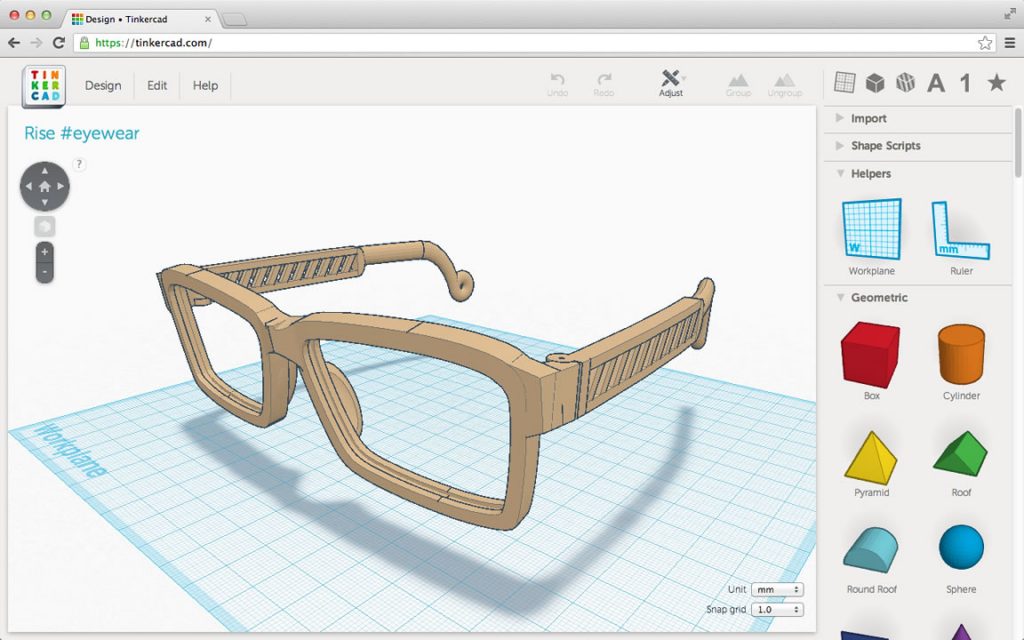

3d Printing Patterns: 6 Significant Developments In addition, they are hing on granite plates, each considering 150 kgs. The lights in the lab are also battery-powered because the magnetic fields generated by rotating existing from an outlet would certainly disrupt the little electrical currents and also voltages required to regulate the nanoprinting process. Integrated deposition modeling, or FDM basically, has stood apart as one of the most commonly made use of 3D printing strategy at the consumer degree. As a result, the modern technology has actually been extensively polished and also changed for the desktop computer. Comprehending which techniques of 3D printing to make use of is a difficulty by itself.Ctrl + P: 3D Printing an F-35 Cockpit - Lockheed Martin

Ctrl + P: 3D Printing an F-35 Cockpit.

Posted: Wed, 25 Jan 2023 08:00:00 GMT [source]

Publishing Solutions

Wherever traditional procedures reach their economic limitations as a result of cost-intensive mold building and construction or changeover times, additive 3D printing offer crucial economic advantages. At the very same time, the public health and wellness emergency has had a considerable impact on the international supply chain. 3D printing provides considerable pledge in the health care area, specifically as a result of its capacity to create extremely tailored products at the point of care. As 3D printing is adopted even more widely, regulatory oversight must adjust in order to keep up as well as make certain that the advantages of this technology surpass the prospective threats.- Could it at some point drive customers to take on 3D printing quicker and have a 3D printer in every residence?

- Figure 4 illustrates just how SHA-256 verification is installed in a 3D printer and also buddy ink cartridge.

- With this speed comes substantial expenses-- presently, the only makers in this room expense more than a million bucks.

- Photopolymerized resin likewise has bad mechanical homes that are required for difficult tissue engineering.

Desktop Composite 3d Printers

SLS resembles 3DP in binding with each other powder fragments in slim layers other than a carbon dioxide laser light beam is utilized. The laser scans the surface of the powdered polymer fragments in a details 2D pattern to sinter by heating them over the glass change temperature. During sintering, molecular diffusion along the outermost surface of the fragment result in neck development between neighboring fragments. After one layer is created, the piston including the component is reduced and a fresh layer of powder material is rolled throughout the top surface area. Unbound, loose powder is gotten rid of after the part is finished and also is warm dealt with to accomplish full thickness. Short-lived assistance frameworks are not required, unlike in SLA, because unbound strong bits support any type of cantilever structures. Additive shoe production 4.0 Just how powder-based 3D printing is revolutionizing tomorrow's running. The straight, additive production of steels is getting more and more market share. Whether sand mold and mildews for steel spreading or investment spreading plastic shed patterns, foundries benefit in both cases from the numerous benefits of additive 3D printing. What is 3D printing as well as where are their feasible applications as well as what is it in fact with the ability of?Is The Razor-razorblade Model Secret To 3d Printing Market Development?

Also at less than $1,000 today, a 3D printer is still really expensive for a customer product. The 3D printing strategy has been advancing to produce 3D models as well as prototypes in the automobile, aerospace, medical care, as well as customer industries. Connoisseurs believe that these 3D designs could help firms finish a job in less time and/or with less sources. Because sintering does not lead to complete melting of the powder particle, the porosity between the original particles can be protected, and a vast array of pure as well as combination of products can be refined. Indirect 3DP publishes a mold and mildew which is after that cast with the last polymer and porogen products. Materials formerly used in indirect 3DP to print the mold and mildew consist of commercially offered plaster powder (i.e. calcium sulfate hemihydrate plaster powder) and water-based binder. The mold and mildew is then cast with a slurry of naturally degradable polymer liquified in solvent mixed with porogen (i.e.polylactide-- coglycolide in chloroform combined with NaCl). The resulting porous scaffold can be seen in Figure2 with villi-shaped columns. Cells designers have used 3DP to fabricate permeable ceramic scaffolds with fully adjoined channels straight from hydroxyapatite powder for bone substitute.What are the 3D printing methods?

There are a number of types of 3D printing, which include: Stereolithography (RUN-DOWN NEIGHBORHOOD) Discerning Laser Sintering (SLS) Merged Deposition Modeling (FDM).

Social Links