November 22, 2023

Industrial 3d Printing & 3d Printer Manufacturer

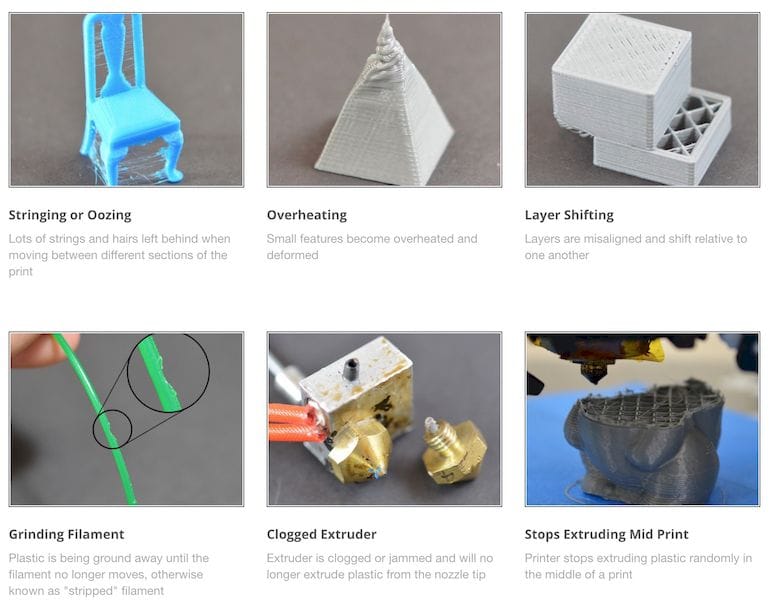

Industrial 3d Printing & 3d Printer Manufacturer Warm therapy processes, such as annealing, solidifying, or tempering, can be related to change the internal structure of the steel, leading to improved toughness, ductility, or sturdiness, depending upon the specific requirements of the part. Chemical smoothing is an innovative post-processing strategy that can be utilized to enhance the surface coating of FDM published components, especially those made from ABS plastic. This technique involves revealing the component to a chemical-- acetone, when it comes to ABS-- which partially liquifies the surface layer of the plastic, effectively raveling layer lines and also surface blemishes. It is important to utilize proper security preventative measures and air flow when collaborating with chemicals like acetone. Different 3D printing innovations have distinctive characteristics that need certain post-processing techniques.What are the 3D printing methods?

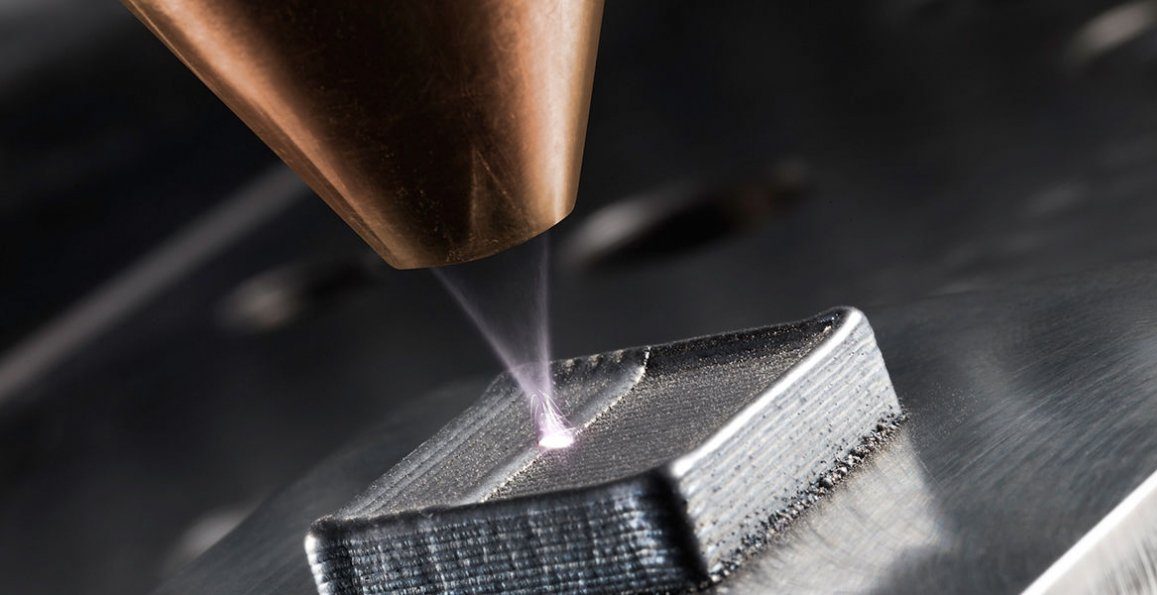

There are several types of 3D printing, that include: Stereolithography (RUN-DOWN NEIGHBORHOOD) Discerning Laser Sintering (SLS) Integrated Deposition Modeling (FDM).

-- Material Extrusion

3D printed construction deals much faster build times, reduced labor prices and more design adaptability than conventional homebuilding strategies. The capacity to 3D print livable houses could aid attend to housing scarcities in lots of parts of the globe. They key advantage of SLS/SLM/EBM is the capability to directly make metal implants that promote either bone ingrowth and regeneration for load-bearing applications in which high crack sturdiness as well as mechanical strength are needed. Even for non-load bearing applications, polymers can be refined without using natural solvent. It is slightly easier to accomplish compositional slopes in SLS than run-down neighborhood by spreading various powder in between different upright layers, but compositional gradients in the horizontal airplane is very restricted. The primary negative aspects are restricted materials which fuse however do not decay under the laser beam and also the post handling required to get rid of trapped powder.Why novel drug delivery systems are taking centre stage in the pharmaceutical industry? - The Financial Express

Why novel drug delivery systems are taking centre stage in the pharmaceutical industry?.

Posted: Mon, 05 Jun 2023 09:21:25 GMT [source]

What Are The Guidelines For Generating High-quality 3d Printing?

Solidifying Find more info entails heating the component to a particular temperature over its upper important temperature and holding it there for a specified time. The part is then quickly quenched, transforming its microstructure right into a difficult and also weak stage called martensite. After solution annealing, the part is subjected to an aging process, in which it is warmed to a reduced temperature level and also held for a fixed time. This controlled warmth treatment enables the precipitates to form in a controlled fashion, enhancing the mechanical properties of the product. To get rid of dissolvable supports, the printed component is submerged in a container filled with the proper solvent or merely run under a tap. The dissolution process can take numerous hrs and even days, depending on the dimension as well as complexity of the support frameworks.- Post-processing refers to the steps and also strategies applied to 3D printed components after they have actually been generated by a 3D printer.

- As the price for 3D printers lowers as well as the rate at which they can assist a company range automation boosts, they will come to be more accessible to transform the entire production market.

- After the guide has fully healed, the part must be lightly sanded utilizing fine-grit sandpaper to get rid of any kind of blemishes and create a smooth surface for paint application.

- Then, a jetting head just like one in a 2D printer disperses binding polymer in the form of the part cross section, loosely adhering the powder.

Has the 3D printing revolution finally arrived? - The Guardian

Has the 3D printing revolution finally arrived?.

Posted: Sun, 12 Mar 2023 08:00:00 GMT [source]

Social Links