November 7, 2023

Print High Quality Repairing Overview

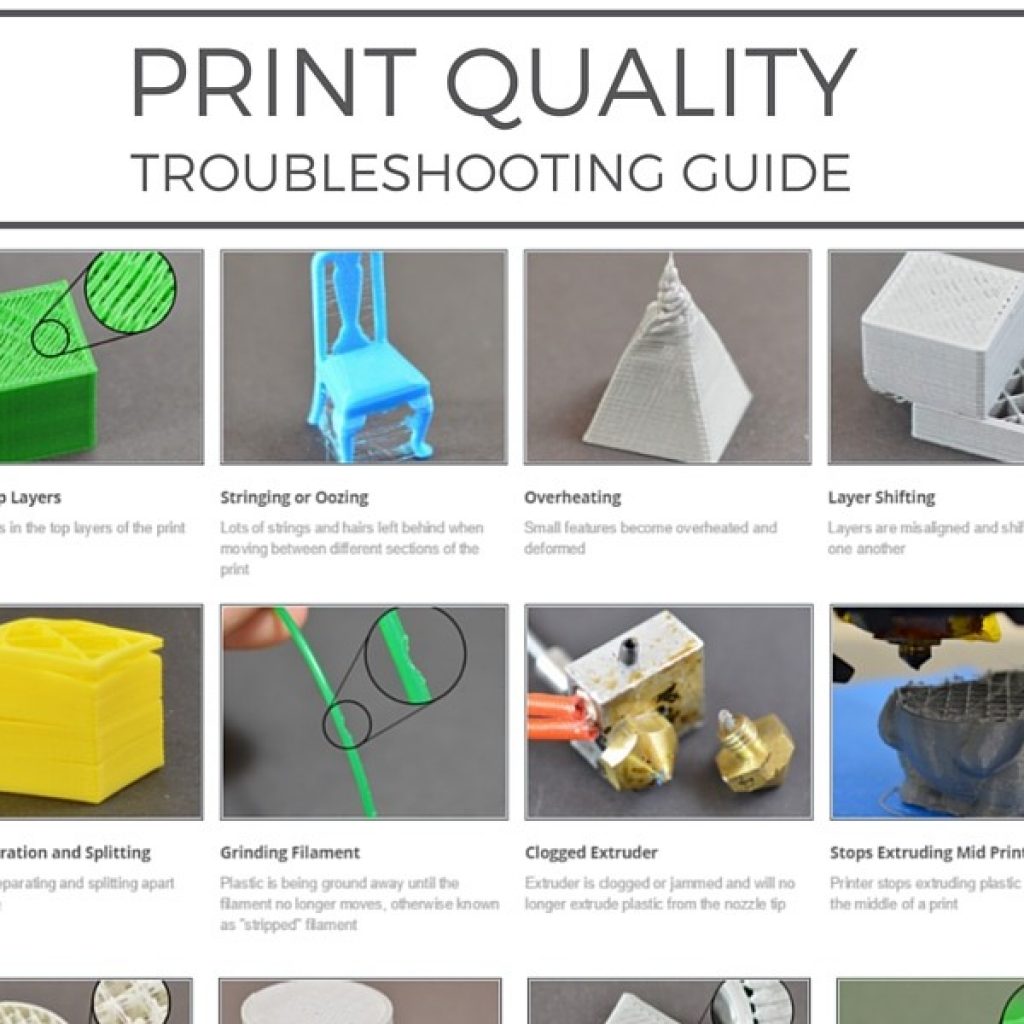

3d Printing Troubleshooting: All Problems & Options The complimentary movement of the nozzle can be readjusted as well as managed via the slicer settings. Identify that the nozzle takes the shortest feasible path to the next printing point. As an individual, you need to recognize the ideal printing temperature levels for the filaments you utilize. This is yet one more common 3D printer problem that numerous novices face. Stringing is an issue that takes place when slim strings of material, similar to whiskers, remain externally of a 3D printed component, impacting the print's surface area finish.What are the usual 3D printing troubleshooting problems?

- Not Extruding at Beginning of Print. Printer does not extrude plastic at the beginning of the print.Not Sticking to the Bed.Under-Extrusion. Over-Extrusion.

- Spaces in Top Layers.Stringing or Oozing.Overheating.Layer Shifting. Size.

- One feature to consider when

- creating your product is it's scale.The resolution.

- During additive production, the resolution refers to the thickness of each layer of product being'applied.Wall thickness.The orientation.The option of

- material.Design equilibrium. When a PLA filament absorbs dampness, it swells up, increasing the risk of extruder jams. Dampness also causes PLA to create prints with bubbles and also gaps externally, as a result spoiling your prints

- .

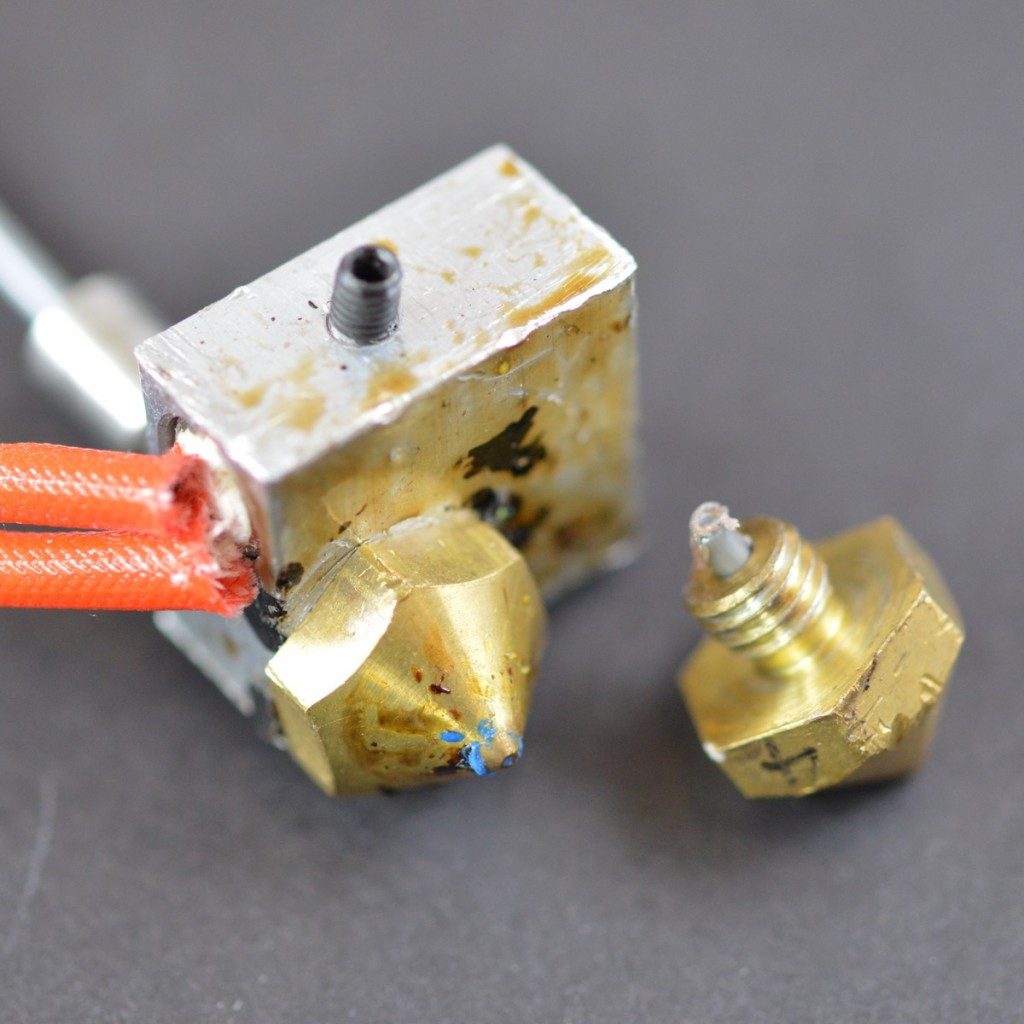

Irregular Extrusion: Exactly How To Fix Over Extrusion

Although the printer has a failsafe that makes the motor quit to stop further damage, other parts might proceed working. With the open-loop control system, there's no way for your 3D printer to keep an eye on the head's location. You can input information, and also it will take the nozzle to that place, yet there's no warranty that it's publishing on top of what it should. The head can likewise move throughout the process, not recognize the adjustment, and also maintain working. You can change the height by going to your setups and also considering the layer tab. Select a dimension that is 20% smaller than the diameter of your nozzle to make sure whatever bonds together.- If the worth of the 'infill overlap' setting is a no or even isn't evaluated all, then the issue will likely appear.

- Wipe the rods and alter the oil, and the trouble may be fixed.

- Most likely, the 3D printing surface of that layer is over-extruded which's why the nozzle scraped it in the action.

- Problems with stringing and also oozing make your 3D prints look hairy, like a spider attempting to construct an internet between various parts of the framework.

Initially Layer Issues

Border adds a layer of lines that emit from the point of contact Discover more here in between the model and also platform. It doesn't make use of as much product as the various other choice, we recommend it more for various factors. But keep in mind that for cutting the it away, you will likely need to make use of a knife. You can find an overview for your specific 3D printer on exactly how to tighten up the belts. Some 3D printers have straightforward tensioners at the end of the axis that you can manually resort to tighten them. Another point you can do is place stiffer springtimes on your bed to decrease the bounce. The Marketty Light-Load Compression Springs work fantastic for a lot of other 3D printers available.Repairing

To stop the cooling of the preliminary layers of the print, one troubleshooting method is to shut off the follower. At least, follow this advice for the very first few layers while printing materials like ABS, Nylon, and so forth. In printing, the retraction range is extremely essential.3D Printing News Unpeeled: 316L Qualified for the Navy, Markforged & Continuous Lawsuit, Teddy Bears - 3DPrint.com

3D Printing News Unpeeled: 316L Qualified for the Navy, Markforged & Continuous Lawsuit, Teddy Bears.

Posted: Thu, 06 Apr 2023 13:42:31 GMT [source]

Social Links