November 7, 2023

Sorts Of 3d Printing In Steel

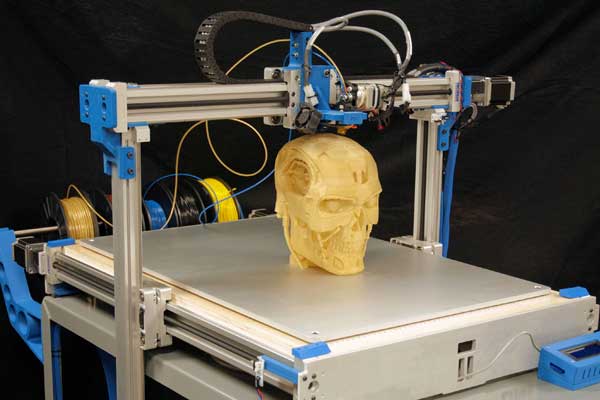

Sorts Of 3d Printing In Steel Rather than spreading powder on a bed and also melting it with a laser, DED devices precisely blow powder out of a print head onto a part, utilizing an on-head laser to fuse it to the part in construction. And basically this printhead resembles a big cake-icing device that extrudes concrete, among one of the most durable materials in the world. In spite of the optimism for development in additive manufacturing, organizations have yet to fix all the challenges with 3D printing. Whereas nearly half of 2019 participants detailed "expense of products" as a concern, just concerning two-fifths did this year. While 3 years of 3D printing may not seem especially long in comparison to traditional production techniques, additive manufacturing has been highly transformative in a large range of sectors.- Sustainability and responsibility are essential worths of voxeljet AG as well as stand for the additional advancement of our 3D printing services.

- Solidworks supplies advanced devices to create intricate parts prepared for 3D printing.

- Electroplating is a sophisticated post-processing technique utilized to add a metallic layer to 3D printed parts.

- As well as not to forget with an excellent possible for price optimization in the manufacturing procedure.

- A number of intended deep space missions will make use of significant elements generated on 3D printers.

When Were 3d Printers Introduced?

3D printing starts with a digital data stemmed from computer system helped layout software application. Once a layout is completed, it should then be exported as a standard tessellation language data, meaning the documents is equated into triangulated surface areas as well as vertices. Build durable, low-volume production get rid of a range of engineering-grade thermoplastics. Our manufacturing solutions help you get your product right into the hands of clients a lot more successfully. In Accrington, Structure for Humanity wants to place people on the real estate ladder that otherwise would never ever have the ability to afford it. Among the houses has been reserved for Mark Harrison, 44, a professional from the community that got a clinical discharge from the Army in 2001 after 2 tours in Bosnia, as well as was later on diagnosed with PTSD. The SHA-256 interaction entails a symmetrical key-based bidirectional challenge-and-response authentication scheme. It is a hand-shaking procedure in which one party offers a secret inquiry or difficulty to another celebration.Which innovations are currently made use of in 3D printing?

- Material Extrusion.Fused Deposition

- Modeling( FDM) 3D Bioprinting.Construction 3D Printing.Vat Polymerization.Stereolithography (RUN-DOWN NEIGHBORHOOD)

- Digital Light Handling( DLP) Fluid Crystal Present( LCD)

What Is 3d Printing And What Is Additive Manufacturing?

When these possibilities fulfill interesting originalities, innovative products are created that have the prospective to alter our world. Along with our consumers we prepare to enter this new territory, to shape the future together. Electromobility, crossbreed drives, resource performance, sustainability and also digitalization are ushering in a lasting improvement in the vehicle industry. Not just did this assist them to increase the manufacturing procedure yet by printing the specific geometry they required, they were able to cut prices. Today, r & d exceeded prototyping as one of the most popular 3D printing application and every various other use situation has actually dramatically enhanced. The portion of firms leveraging additive production to construct manufacturing components and jigs, components and also tooling has actually about doubled considering that 2017 as well as use for production components has actually nearly tripled. Understanding all the intricacies within the 3D printing procedure can be a difficult task. Here are several of the usual inquiries you could have concerning 3D printing as well as additive manufacturing overall. Additionally, the advancement of brand-new 3D printing innovation kinds coincides with raised need for more streamlined vehicles and also light-weight elements.SPEE3D celebrates success in US defense challenge with Cold ... - TCT Magazine

SPEE3D celebrates success in US defense challenge with Cold ....

Posted: Thu, 18 May 2023 07:00:00 GMT [source]

Social Links