November 7, 2023

3d Printer Troubleshooting Directions To Repair Problems With 3d Printing

Troubleshooting & Supplies 3d Printing Additive Production Sbu Libraries At Southwest Baptist College Collections Being mechanical gadgets with a number of controllable elements, a 3D printer need to be tuned properly in order to appreciate effective 3D prints. Also machines that are taken into consideration "not damaged" and also "in good functioning order" can extremely quickly create bad 3D prints otherwise set up effectively. The desired model has actually been cut properly as well as the printer has been configured, nevertheless, nothing shows up out of the nozzle bar the tinyiest bit of oozing plastic. If you are lucky this can be found early as the quality of your prints will certainly lower as the amount of carbonised filament boosts. The print separates from the print bed and move throughout printing. After some printing time, a ball of material can form around the nozzle.- A few of these concerns can be successfully stayed clear of by using OctoPrint as well as its plugins.

- In order to detach the design you'll need to place it under warm water and also carefully remove the surface area glue.

- Stepper controllers with their potentiometers changed also reduced (counter-clockwise), causing stepper to miss out on actions.

- Furthermore, I have a list of items to check around the printer on the Framework tab of my Calibration page that must act as a handy guide to resolve.

- Filament material and/or brand is being changed on a regular basis without cleansing in between.

Material Feed

Printing also warm and making use of insufficient retraction setups. Make sure you're not establishing your bed temperature level close to the glass transition temperature level of your filament (keep 10 ° C listed below). You can find rigid.ink glass transition temperature in the downloadable datasheet for your material on the product web page setups tab. PETG typically publishes far better with a higher nozzle to bed range to stay clear of the nozzle grabbing filament that might trickle on your print later on throughout the print. Also, the extra distance helps avoid too much adhesion problem that as an example might take place when printing on glass or PEI beds.3D Printing 1990: “The Present State of Accuracy in Stereolithography” - 3DPrint.com

3D Printing 1990: “The Present State of Accuracy in Stereolithography”.

Posted: Thu, 16 Mar 2023 07:00:00 GMT [source]

Just How To Take Care Of: The Nozzle Is As Well Close To The Print Bed

If the nozzle is still blocked, then the filament might be pushed with one more item. Heat up the hot end to 220 ° C if you're reusing PLA as well as use an additional little brand-new filament to push this through. But don't do it too hard, so you can avoid flexing the printer rods. The signs and symptoms are easy to overlook-- places of filament or nicks in the wall surfaces and also print top quality changes. The results are normally disregarded as well as credited to a variative nature of 3D printing, but sometimes the reasons are major. Cleaning up techniques such as Atomic Pull or Cold Pull can assist remove it.What are the common 3D printing troubleshooting problems?

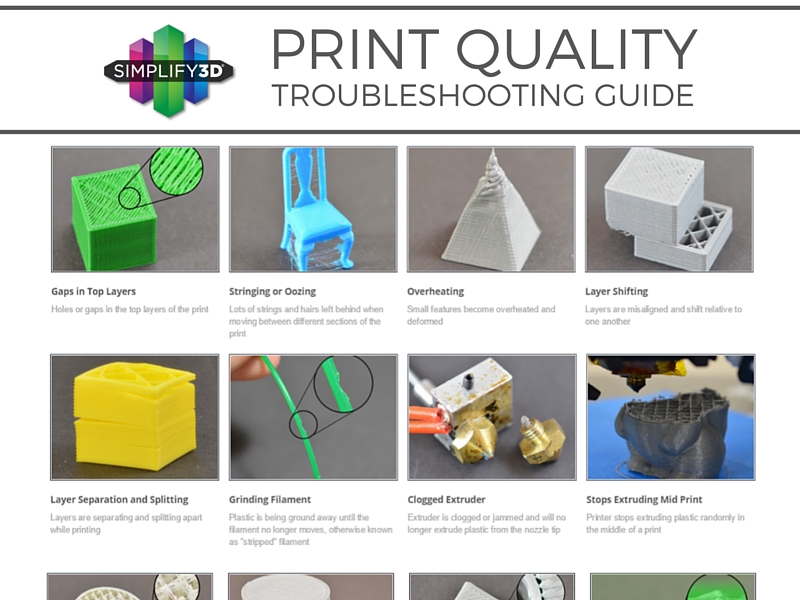

- Not Extruding at Begin of Publish. Printer does not extrude plastic at the start of the print.Not Adhering to the Bed.Under-Extrusion. Over-Extrusion.

- Gaps in Leading Layers.Stringing or Oozing.Overheating.Layer Shifting. Dimension.

- One attribute to take into consideration when

- developing your thing is it's scale.The resolution.

- During additive manufacturing, the resolution refers to the thickness of each layer of material being'applied.Wall thickness.The orientation.The selection of

- material.Design balance. When a PLA filament absorbs moisture, it swells up, increasing the risk of extruder jams. Dampness additionally triggers PLA to produce prints with bubbles and gaps on the surface, for that reason wrecking your prints

- .

System Not Level

In 2021, Paul persuaded Scott to collaborate as well as launch a new online project built around their shared passion in 3D printing, 3DGearZone. Scott brings 12 years of https://objects-us-east-1.dream.io/custom-printing/Offset-Printing/history-of-printing-press/recent-advancements-in-3d-printing-of-biomaterials-journal-of-organic.html electronic advertising experience and a hardcore job values to his new enthusiasm for 3D printing. If he is not working with this company, he is most likely taking a trip and also Overlanding across The United States And Canada with his spouse and 2-year-old kid in their Jeep Rubicon. It's also feasible to produce an obstacle in between the printer as well as the surrounding air by making a cardboard boundary or hanging a protective drape around your print area.Canada’s Auto Parts Suppliers to Debut EV with 3D Printed Chassis - 3DPrint.com

Canada’s Auto Parts Suppliers to Debut EV with 3D Printed Chassis.

Posted: Tue, 03 Jan 2023 08:00:00 GMT [source]

Social Links