November 7, 2023

44 Typical 3d Print Problems Fixing Issues 2023

Brand-new Guide Makes It Simple For Anyone To Enhance Their 3d Print High Quality Software Talk Manufacturing Maximum layer height must not go beyond 75% of your nozzle size (i.e. 0.3 mm for a 0.4 mm nozzle). Breaking happens when 3D printing layers separate as a result of the pressures exerted on the print when layers cool down at a various rate. Warping pressures surpass the layer bond strength and also the layers just separate. Flexible filament usually requires longer retractions as it extends while being drew backwards. We recommendFLOSS, a high-performance cleaning filament, to make preventive upkeep very easy. Extrude a bit of rigid.ink Floss regularly, such as between material modifications as well as the risk of obstructions must be decreased drastically.UltiMaker Releases First 3D Printer in Nearly 5 Years: the S7 - 3DPrint.com

UltiMaker Releases First 3D Printer in Nearly 5 Years: the S7.

Posted: Tue, 24 Jan 2023 08:00:00 GMT [source]

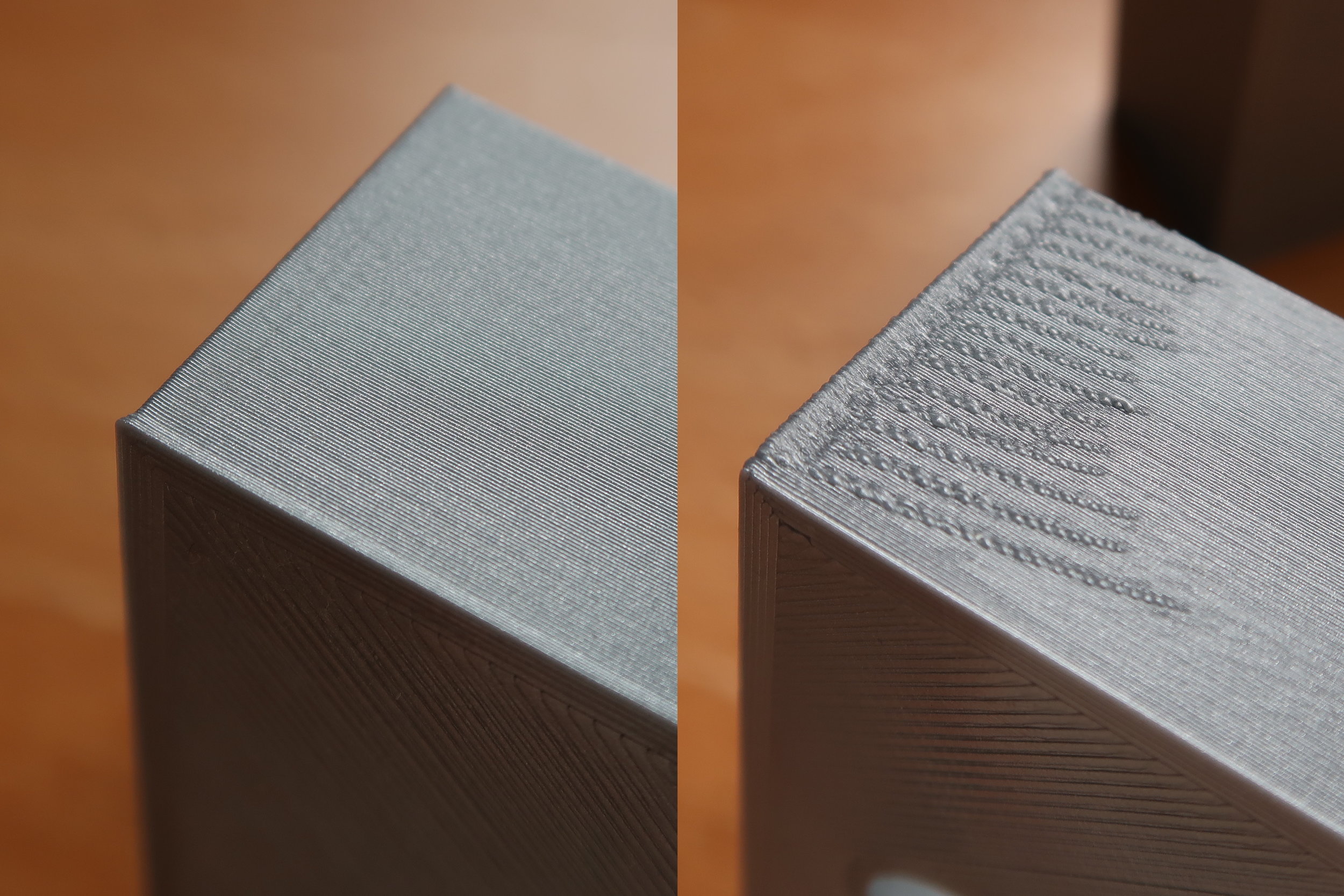

Infill Poking Through Summary

If the nozzle is still damaged after that you will certainly need to dismantle the hot end. If you're not aware of the procedure, it's better to track all the actions you experience, making note or photos, which will come in handy for reassembling. It will likely aid you understand it needs to be dismantled.- This can be simple, possibly you warm up the nozzle for a filament swap and afterwards obtain distracted.

- For that reason, make certain to give minimum factors with assistance frameworks or just change their angles to a lower degree.

- Stringing may happen if the print rate is slow-moving because the filament constantly exudes out of the nozzle and forms a string.

- The Marketty Light-Load Compression Springs job excellent for a lot of various other 3D printers available.

Ghosting (you Can See The Infill From The Outside)

If your printer has a warmed bed, heat it to the temperature level suggested by the printing material. This makes certain that the print stays touching the print bed thereby protecting it from creating pasta. Publish speed is additionally taken into account when getting rid of stringing. Stringing may happen if the print rate is slow-moving because the filament constantly exudes out of the nozzle as well as forms a string. Because of this, the nozzle needs to move much faster from one location to the following, giving the filament much less time to develop strings.Triastek Discusses Three 3D Printed Medications Now Being Studied - 3DPrint.com

Triastek Discusses Three 3D Printed Medications Now Being Studied.

Posted: Thu, 05 Jan 2023 14:30:13 GMT [source]

Social Links